Welding principle and classification

As a heat source for welding and welding, laser has the advantages of excellent collimation, high beam energy density, small acting area, fast temperature raising speed, fast condensation, etc. In the welding process, the laser beam is acted on the area to be welded through the optical path system composed of transmission or energy fiber, and the plastics in the thermal acting area are melted each other. The melted material forms a new interfusion material, so that the welded parts are connected, laser welding is divided into welded joint type or galvanometer type, and the light source is mainly semiconductor and optical fiber.

Semiconductor laser power supply: Professional semiconductor power supply, embedded constant temperature algorithm, closed-loop power control; High power semiconductor laser: direct semiconductor laser, 100W or 200W according to the working efficiency selection =915nm;

High energy anti-reflection fiber:

Step energy fiber, core diameter 400um, length 5m; 100um. The minimum spot diameter is 0.1mm and the maximum is more than 30mm.

Semiconductor laser Semiconductor 100W-200W, 915nm welding head

Customize F100/F125 or select vibration lens 3D workbench 300mmx300mm optional according to requirements

Rotary table (optional)

Industrial computer monitor

Infrared online thermometer PID algorithm software, response speed 20us

Software SYSTEM OSUN WELDING SYSTEM

Cooling system Air-cooled or water-cooled

Visual automatic positioning (optional)

Automatic height measurement (optional)

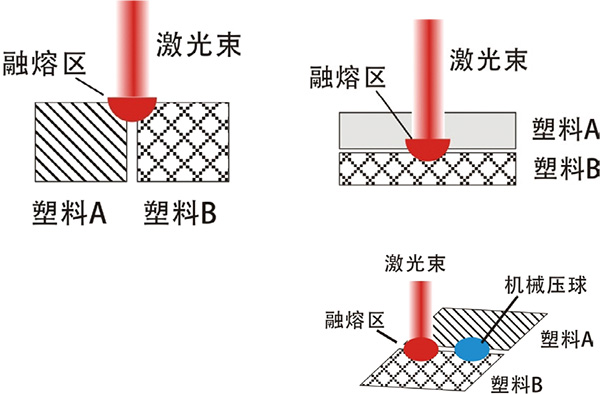

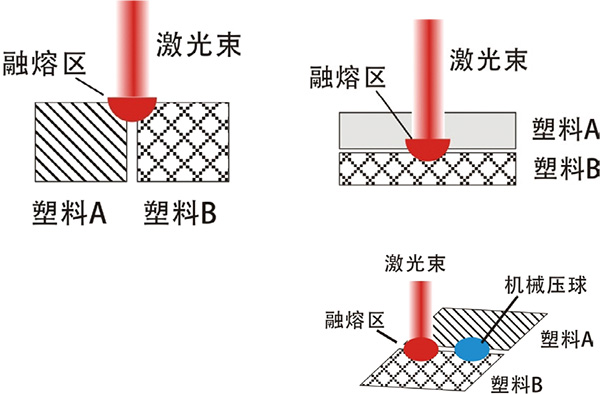

1. Laser butt welding

The two light-tight plastics are welded together by melting the two materials at the same time through laser condensation.

2. Laser penetration welding

One kind of plastic is transparent, the other kind of plastic is opaque, and the laser transmits through the opaque plastic junction, forming a melt pool at the junction of the two materials and welding together.

3. Laser mechanical composite welding

After laser butt welding, mechanical compression is added to make the welding surface smooth and smooth.