Device description

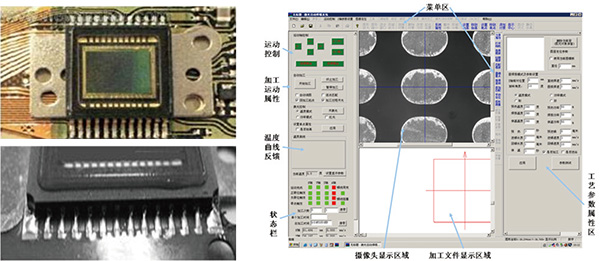

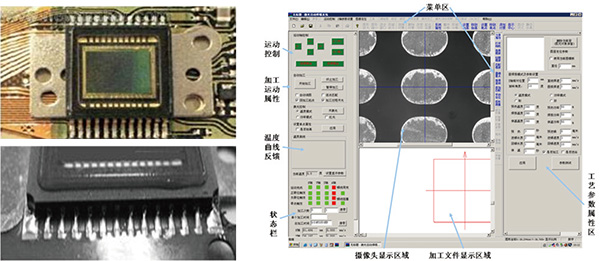

The traditional welding method has the shortcomings of large consumption of soldering iron head, and it must be contact welding. The new direct diode laser automatic tin welding makes up for the shortcomings of traditional welding processing. At the same time for mobile phone CCD parts, LCD parts, mobile phone miniature receiver, handheld computer HDD parts LCD parts and micro motors, micro transformers, but also for the application of LCD TV, high-end digital cameras, aerospace military manufacturing, high-end automotive parts manufacturing and other fields of processing to provide process support.

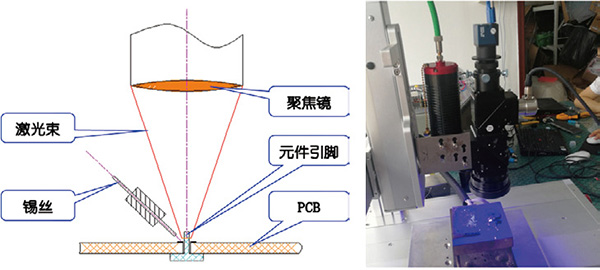

The laser soldering process is as follows:

The laser soldering process is as follows:

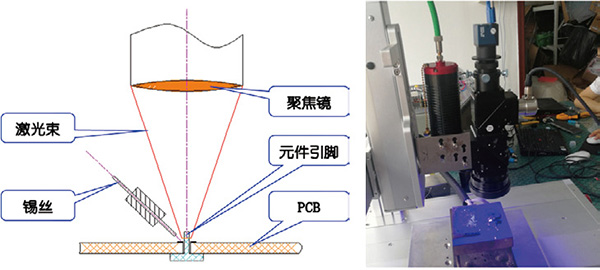

1. Use laser as heat source to irradiate the solder parts

2. Heat in the irradiated part (surface heat)

3. Make the surrounding heat conduction to melting temperature, and through the temperature

Closed-loop monitoring maintains a stable temperature.

4. Provide solder (or first spot solder paste and place tin block)

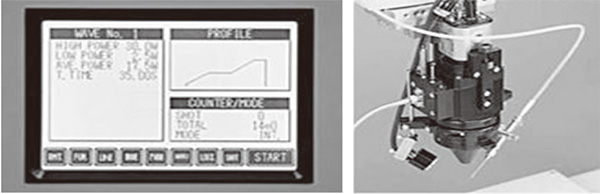

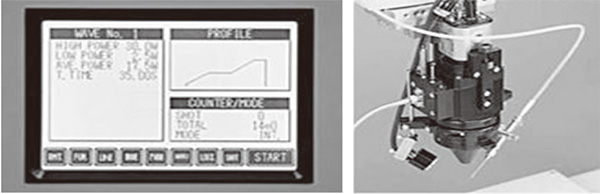

The important parameters of the selected laser welding system are as follows

The important parameters of the selected laser welding system are as follows

Laser output wavelength :808nm

Maximum laser output power :100W